SPECIALIST PURPOSE ENGINEERING

Specialist Purpose Engineering

Hartech Automation specialises in the design, manufacture and installation of automation systems and special purpose machinery.

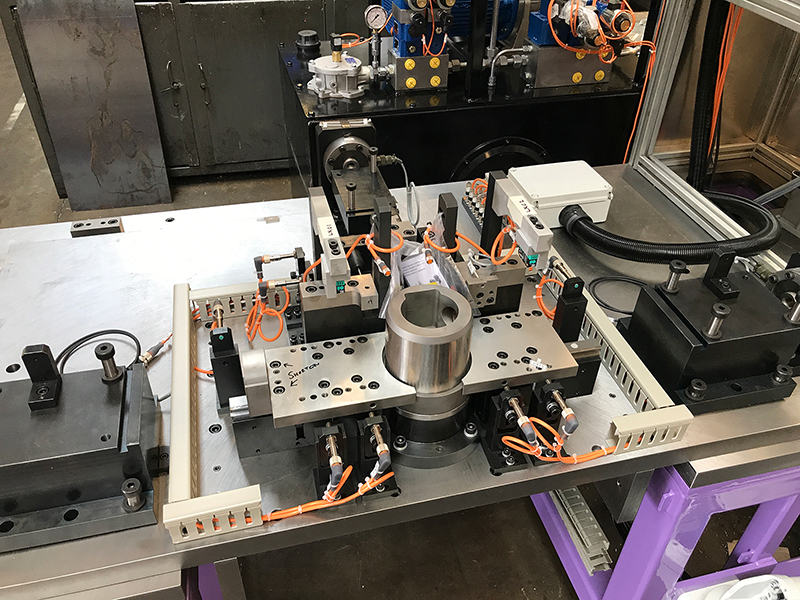

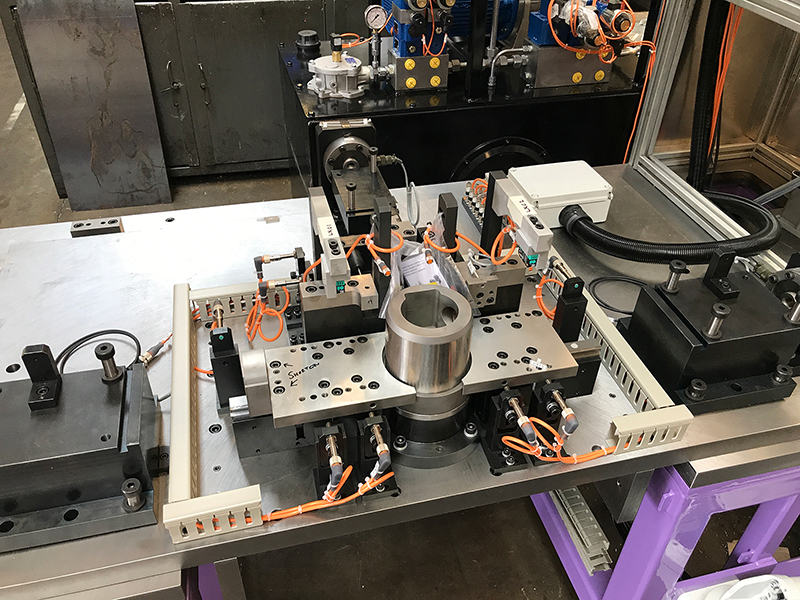

Bespoke machines are engineered for a particular purpose requiring tooling, jigs and multi-axis CNC machined parts from single items to batch runs. By working in close collaboration with our mechanical design engineers, electrical design engineers and control software engineers as well as tapping into the expertise of a range of associates, our team can design and manufacture a ‘Special Purpose Machine’ in conjunction with an automation solution for almost any application.

Every machine we design and build is unique in its concept and manufacture with each engineered project adding to our expertise and knowledge of what we can do for new clients.

Examples of specialist machines and bespoke automation solutions delivered include:

- Bush Press

- Welder

- Water Filter – Gestamp

In addition to specialised automation systems for clients throughout the UK market, the business is gaining a reputation for multi-national projects and has supplied automation systems and special purpose machines to USA, Germany, Poland, China and Croatia.

Finding solutions to your most complex challenges:

Our logical step-by-step process begins by clearly grasping exactly what you want to do. It’s from initial meetings that we can brainstorm our approaches and select the most cost effective method for achieving your requirements, or ‘customer user specification’.

From here we progress to the Functional Design Specification in consultation with our mechanical, electrical and control software engineers we produce a customer blueprint for agreement before proceeding to manufacture.

Our skilled software team has over 20 years’ industrial experience in the following manufacturers:

- Siemens (PLC, HMI, Drives, Scada, PCS7)

- Rockwell Automation (PLC, HMI, Drives, SCADA)

- Mitsubishi Automation (PLC, HMI, Drives, SCADA)

- Omron Automation (PLC, HMI, Drives)

The Functional Design Specification is the basis upon which the project progresses. After a number of planning meetings, a 3D modelling and ‘proof of concept’ testing before manufacture is produced and reviewed before passing to our mechanical and electrical manufacturing teams to produce the machinery to the agreed design and specification.

The special purpose machinery and equipment once engineered, undergoes an internal factory acceptance test (FAT) before being released for installation and commissioning.

Examples of specialist machines and bespoke automation solutions delivered include:

- Bush Press

- Welder

- Water Filter – Gestamp

- ?????

In addition to specialised automation systems for clients throughout the UK market, the business is gaining a reputation for multi-national projects and has supplied automation systems and special purpose machines to USA, Germany, Poland, China and Croatia.

Finding solutions to your most complex challenges:

Our logical step-by-step process begins by clearly grasping exactly what you want to do. It’s from initial meetings that we can brainstorm our approaches and select the most cost effective method for achieving your requirements, or ‘customer user specification’.

From here we progress to the Functional Design Specification in consultation with our mechanical, electrical and control software engineers we produce a customer blueprint for agreement before proceeding to manufacture.

Our skilled software team has over 20 years’ industrial experience in the following manufacturers:

- Siemens (PLC, HMI, Drives, Scada, PCS7)

- Rockwell Automation (PLC, HMI, Drives, SCADA)

- Mitsubishi Automation (PLC, HMI, Drives, SCADA)

- Omron Automation (PLC, HMI, Drives)

The Functional Design Specification is the basis upon which the project progresses. After a number of planning meetings, a 3D modelling and ‘proof of concept’ testing before manufacture is produced and reviewed before passing to our mechanical and electrical manufacturing teams to produce the machinery to the agreed design and specification.

The special purpose machinery and equipment once engineered, undergoes an internal factory acceptance test (FAT) before being released for installation and commissioning.